Burner & combustion management you can depend on

The most powerful, reliable, and safe burner and combustion management solutions. Your single source for key combustion products, including BMS, Fuel Trains, Engineered Solutions, 24/7 Support you can count on, and MORE.

See our Products

Get your BMS comparison guide

PF3100 vs PF2200 vs PF2100 Download Profire's complete burner management comparison guide to find which controller best fits your applications.

Get the guideFeatured Case Study

National Grid, New York

Vacuum boiler natural gas

Profire enabled Natural Grid to upgrade their working environment to be safe for their operators and meet compliance standards

View case study

A Complete Solution

Speak with a Combustion Expert to build your solution now

-

Tell us about your heated appliance

-

Receive expert, customized recommendations

-

Total transparency about product capabilities, pricing, and availability

Trusted by

Just a few of the customers who trust us everyday

Profire Blog

Insights and news about the Industry

-

-

-

-

Industry Innovations

Industry InnovationsLeveraging Environmental DNA (eDNA) Technology in the Oil & Gas Industry

“Profire was able to drop our consumption rate by 82 percent. That represents some pretty significant cost savings to us.”

US Oil & Gas Major

Who would you like to connect with?

Call us at

855.PROFIREJob Openings at Profire

Want to join the team here at Profire? Click the button below to view our current positions.

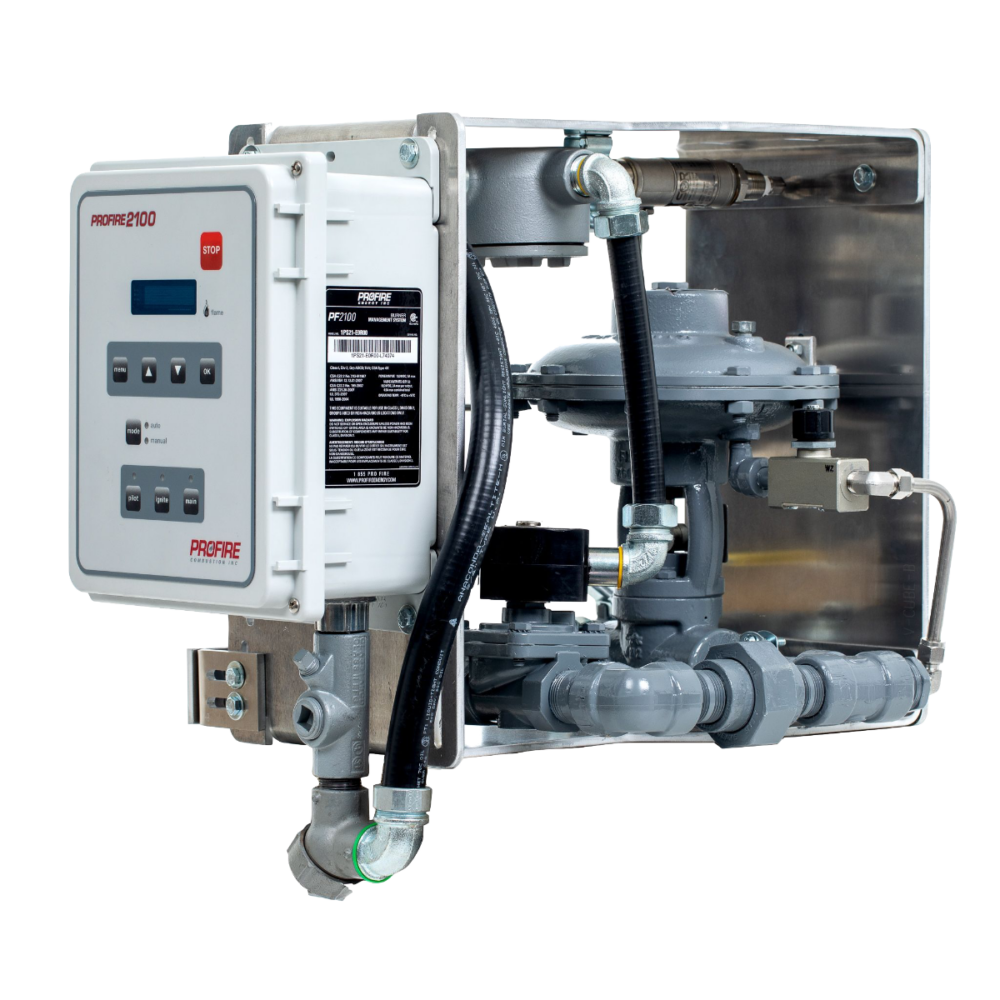

View Current Job Openings PF2200-SB BMS Controller

PF2200-SB BMS Controller

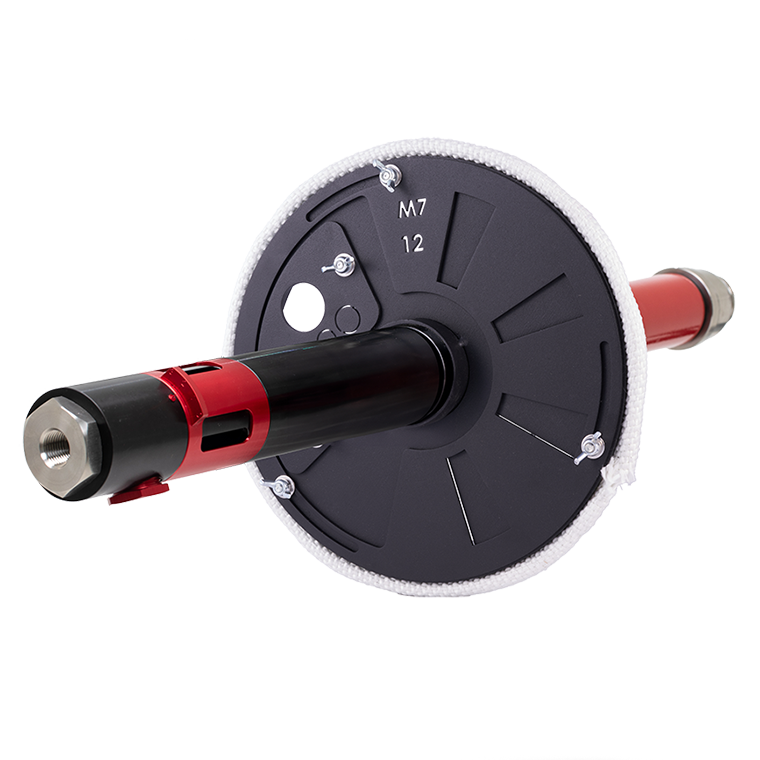

M7 High Efficiency Burner

M7 High Efficiency Burner

PRO QS – 401AP Fuel Train

PRO QS – 401AP Fuel Train

PF3100 BMS Controller

PF3100 BMS Controller

PRO 8 – HBB Fuel Train

PRO 8 – HBB Fuel Train

Inline Pilot

Inline Pilot